The future of Green tech and REMs

By Junior Reporter Richa Patil | January 2026

As global demand for fertilizer, rare earth minerals, and energy resources grows, countries are increasingly competing for access to critical supplies...

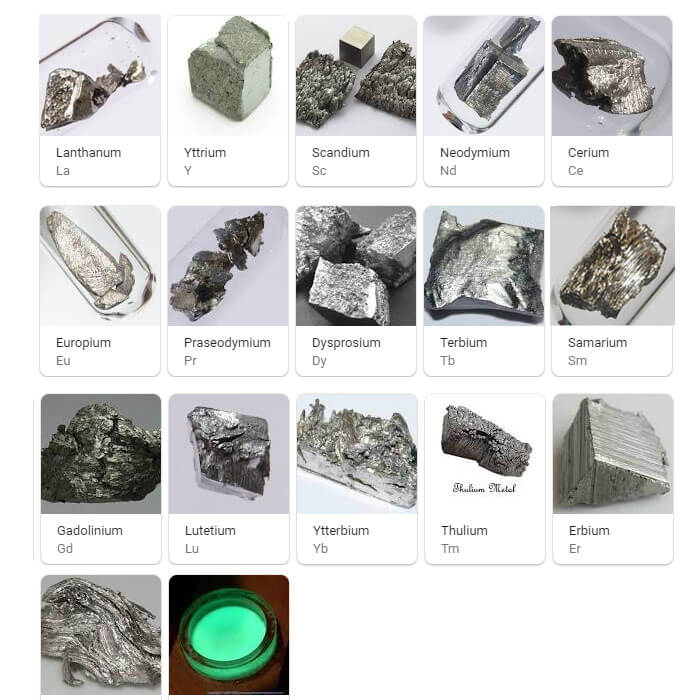

Today we talk about rare earth minerals.

Rare earth metals (REMs) such as neodymium and dysprosium are critical today in many clean technologies — from wind turbines to electric vehicle (EV) motors — because their magnetic properties enable compact, high-efficiency performance. However, a wave of innovation is steadily reducing that reliance by developing alternative materials and designs that either minimize or eliminate the need for these metals.

One striking example comes from the automotive sector. A British start-up, Advanced Electric Machines (AEM), has developed electric motors that completely avoid rare earth magnets, instead using abundant materials such as steel and aluminum while retaining competitive performance. The company has already logged millions of kilometers of real-world use and secured development deals with major global suppliers, with plans to scale production by the end of the decade. Simultaneously, research programs — including those in the United States — are pushing REM-free synchronous reluctance motors that achieve around 90 % of the efficiency of conventional rare-earth-based alternatives, with expectations of mass production by 2029.

Beyond motors, the broader materials science community is pursuing entirely new magnetic chemistries and generator designs. For example, wind turbine manufacturers are experimenting with ferrite or iron-nitride-based magnet systems that avoid rare earths altogether; one prototype wind generator demonstrated a 56 % reduction in mass relative to older REM-dependent designs. Other research efforts are exploring cerium-based and composite magnets that could one day replace some rare earth uses with materials that are cheaper, more abundant, and easier to recycle.

At the same time, recycling and circular-economy initiatives are gaining steam. New aqueous separation techniques and hydrometallurgical improvements aim to recover REMs from end-of-life electronics and EV motors with lower environmental impact than traditional mining, helping keep more material in circulation and reducing pressure on primary extraction. While current global REM recycling is low — less than 1 % of total potential supply — progress in scalable processes could significantly shift the supply landscape in the coming decade.

These developments don’t mean rare earth metals will disappear overnight from green tech — in many high-performance military and industrial applications, they remain hard to replace. But the rapid pace of alternative designs, improved performance of non-REM magnets, and expanding recycling infrastructure strongly suggest that dependence on rare earth mining could substantially decline as next-generation green technologies mature. In the near future, clean energy systems may increasingly rely on diversified materials and smarter design rather than a handful of geographically concentrated minerals.

We believe, however, it is most important to focus on these innovations as the soon emerging green tech without REMs will be revolutionary, and change the economy in ways we can never imagine.